Panasonic Industry, a subsidiary of the Panasonic Group, has announced plans to double its production capacity of MEGTRON multi-layer circuit board materials over the next five years to meet growing demand from AI server and ICT infrastructure markets. The expansion will be implemented at the company’s Ayutthaya plant in Thailand, with an investment of approximately 17 billion yen, equivalent to about USD 115 million. The new facility will be built on the existing Panasonic Manufacturing Ayutthaya property and is scheduled to commence operations in November 2027, with mass production expected by the end of fiscal year 2028.

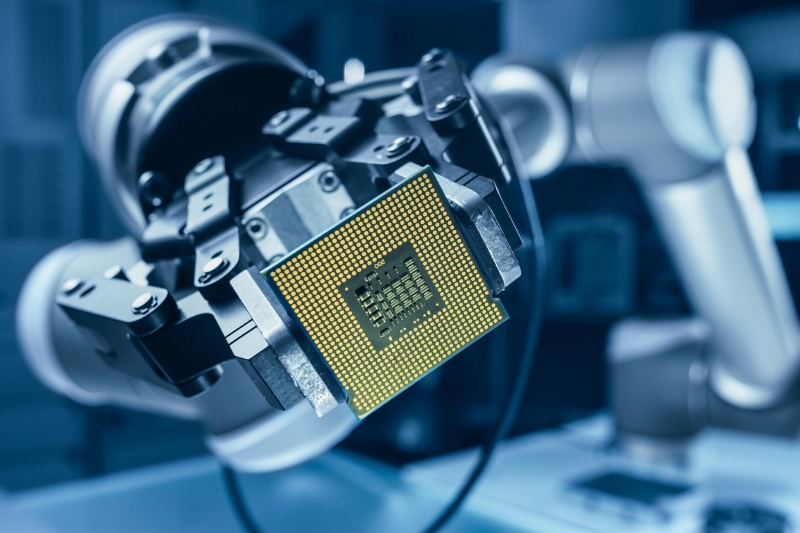

MEGTRON materials are recognized in the industry for their low transmission loss, which minimizes signal degradation in circuit boards used in servers, switches, and routers. These materials are critical for stable and efficient signal transmission, supporting high-speed communication in AI and ICT infrastructure. The rising adoption of generative AI has accelerated the need for reliable high-performance electronic components, making the expansion timely for the technology sector.

The new building, covering approximately 19,400 square meters within the Rojana Industrial Park in Ayutthaya, will be designed according to Panasonic’s “Slim & Smart Factory” concept. The facility will incorporate advanced automation and energy-efficient technologies, aligning with the company’s sustainability objectives while enhancing production efficiency.

The expansion underscores Panasonic Industry’s strategic commitment to innovation in electronic materials. By increasing MEGTRON production capacity, the company aims to support the global rollout of AI technologies and contribute to the development of reliable, high-speed communication infrastructure. The facility will strengthen Thailand’s position as a regional hub for advanced electronic materials manufacturing and demonstrate Panasonic’s focus on integrating technological performance with environmental considerations.

This investment reflects the broader trend of increasing electronic materials production in Southeast Asia to meet rising demand from data centers, AI servers, and ICT infrastructure, positioning Thailand as a key location in the global supply chain for high-performance circuit board laminates.

(Source: Panasonic)